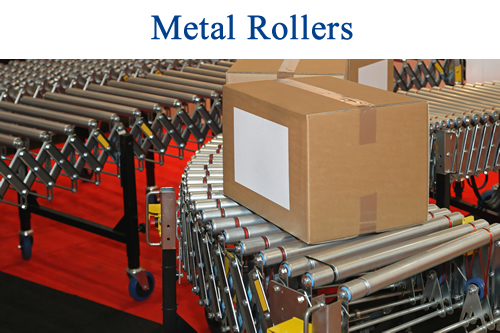

When using a conveyor system with metal rollers it’s important to keep them clean and well-maintained. If you want to continue to run a successful production without interruption, this is the key no matter what industry you’re in. When determining how you’re going to clean your conveyor belt you will want to look at the material being moved and how it affects it, the speed of your belt, and the material it is made from. Part of keeping the belt clean is just making sure boxes don’t pile up or material doesn’t stall and create a build-up.

Why You Should Keep It Clean

Keeping your conveyor system clean is important to continuing production for several reasons. First, you have to look at what will happen if the conveyor goes down for maintenance because something got in and jammed it. You might lose money and you’ll certainly lose valuable production time. You also depending on what you’re moving can contaminate your product which can lead to all kinds of legal issues. You can avoid larger problems later by keeping the conveyor clean and inspecting it periodically to make sure parts don’t need replaced.

When it is Time to Replace your Rollers

You’ll want to inspect your metal rollers to see if they have become worn down. If they have you’ll want to replace them to make sure the conveyor continues to run properly. A reliable roller company can easily replace your rollers quickly so production doesn’t suffer. They provide rollers for all types of industries and even have an option to create your own custom roller if you decide to. If you keep a close eye on your conveyor and keep a policy of inspection in place then you should be able to operate efficiently every day.