When people need tubular heating elements, they rely on an expert manufacturer. The best companies create tubular heaters that are designed to deliver excellent performance in demanding applications. They consider a range of factors, including movement, moisture, dimensional tolerances, operating temperature, the material being heated, and environmental factors when designing these products.

Why Use Tubular Heaters?

People choose tubular heating elements for a number of different reasons. They are versatile, economical, and reliable, and they offer superior heat transfer for applications that involve air, heating liquids, or metals. They can also be used when an application has considerable space limitations, and they allow high dielectric strength and even distribution of heat.

They are used for process air and gas heating, water or liquid immersion, circulation heating, tank wall and pipe heating, and more. They can also be used for radiant heating, vacuum heating, and metal mold and die heating. There are many different applications, which is why they are so popular.

Tubular Heater Examples

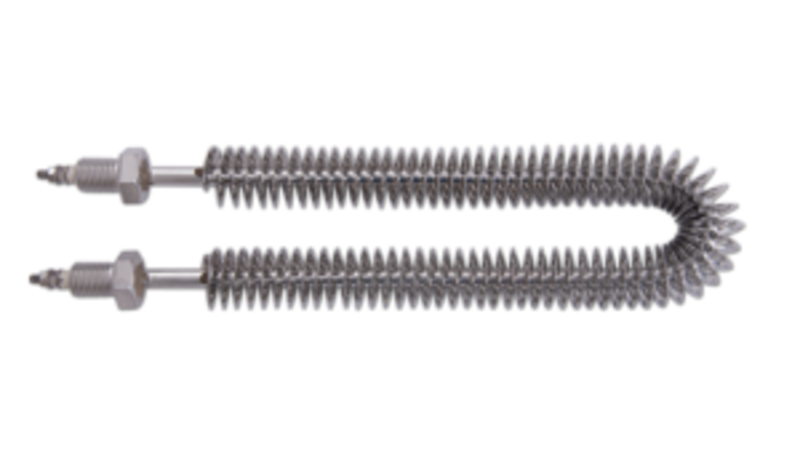

Manufacturers can make different types of tubular heating elements. They make air duct heaters, multi-bend tubular heaters, finned tubulars, straight finned tubulars, and more. Some applications use plate heating or pre-bent tubular, while others need immersion tubular heating elements.

No matter what type of tubular heater their customers need, the best manufacturers can create it. They help with aluminum casted heaters, liquid immersion tubular heating elements, tunnel heaters, and more. They have decades of experience and they produce quality products for all of their customers.