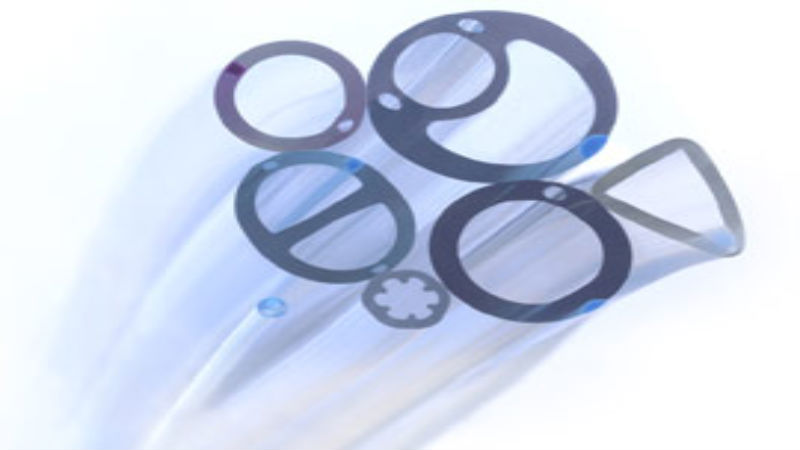

Insert Molding is a metal or plastic insert that is pre-formed and incorporated into a component during the stage of molding or as a part of the after molding stage to increase the strength of the molding or add special features to make it more useful. When these inserts are used in the stage of molding, typical molding machines can make it challenging for users to place inserts into the right place inside of the tool. For this particular process, vertical machines and vertical press machines accompanied by a rotary table are the most effective.

Benefits of Insert Molding

There are many benefits to using insert molding. For starters, it decreases the amount of time that is spent on molding operations. Increases the functionality of the parts and decreases the time of production and assembly. However, there are some other benefits as well.

* Downstream cost reduction: The reduction of secondary post-molding operations is decreased by the creation of components that are more complex than others

* Easy assembly: These metal components that are made with high precision allow the other components to be clipped or screwed together

* Consistency of components: Operator error is nearly eliminated which creates a very high level of precision and consistency

* Complexity of Components: A very basic molding tool can take on a complex component with a simple metal insert

* Decreased weight and size: Even though the physical strength is more than doubled, the molding insert creates a much lighter and smaller component

* Cost reduction: This tool costs much less to manufacture than other tools that are similar

* Design flexibility: Designers like the fact that there are tons of unlimited configurations that this molding process permits

Industries Who Benefit

There are some industries who benefit from using these moldings. These can be used in the military, automotive, electrical, electronics, life sciences, banking, marine, and various other departments and facilities. These moldings are typically found in electrical and electronic pins, switches, mechanical assemblies, fasteners, gears, life science sensors, electrical and electronic connectors and contacts, and various other areas. They can be used in many areas and have many uses.

Conclusion

Understanding more about insert molding will help you to grasp the concept of them and what they are primarily used for. As you probably figured out, it takes a strong team of individuals to get the job done right when it comes to these moldings.