In retail store displays for shelving, storage cubicles or even free-standing racks for hanging clothing items are a costly addition to the inventory. However, with just a bit of creativity and a few simple tools you can actually design your own racks and displays with aluminum tubing and nylon tubing connectors.

The aluminum tubing used for these types of displays is typically square and is one inch in size. There is also a smaller option for tubing and tubing connectors that are three-quarters of an inch, but these are often available only through special order. One inch tubing is very common and should be easy to find at any aluminum supplier.

The Basics

To create any type of rack or display, it will be important to know the specific dimensions and measurements of each component. This will be essential for the aluminum order, but also the shape will determine the appropriate types of tubing connectors to have on hand.

The aluminum can be cut with a circular saw, and it can also be touched up with a grinder to remove any sharp area on the cut ends. Keep in mind, you should also purchase caps for any ends of the tubing that will be left unconnected, such as the arms on a free-standing hanging rack.

Connectors to Have on Hand

Depending on the type of frame or rack you are creating you need to have a variety of tubing connectors on hand. The basic shapes you may need to consider include:

* 2 way 90 – this is a connector to attach two pieces of aluminum to form a 90-degree angle. This could form a leg and a base or a leg and top.

* 3 way 90 – this adds one more dimension and forms the complete bottom and top of a corner of a shelf, table, or box. There will be one insert in the design of these tubing connectors that creates a 90-degree angle going down and two others that go out on either side to form the sides. Each one forms a 90-degree angle with the others.

* 3 way T – this connects two horizontal aluminum sections with one vertical section as in a middle section on the top of a table or shelving unit. Where the two top pieces join there is a flat cap.

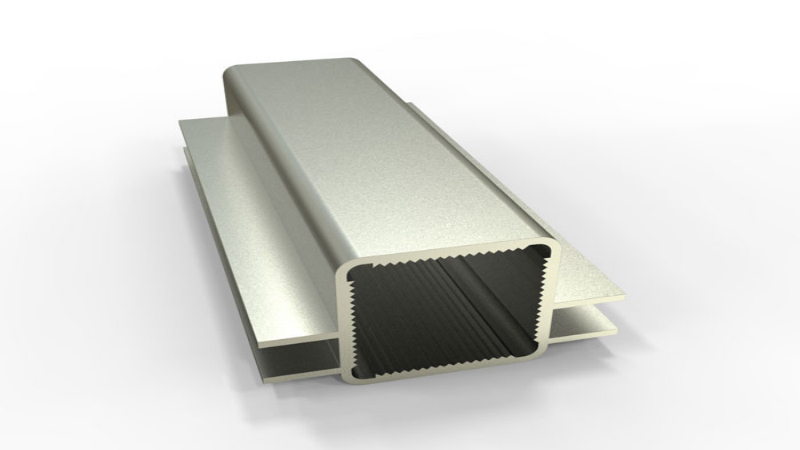

From these basics, there are different and more complex options for tubing connectors. The ends of the connectors simply slide into the aluminum tube, creating a tight, secure connection that can easily be changed, reconfigured and adjusted as display needs change.