Zinc nickel plating is a surface-finishing process that has been turning heads in Indiana. The plating is a combination of zinc and nickel deposited onto a metal surface, resulting in a long-lasting and highly corrosion-resistant finish. There are many uses of zinc nickel plating in Indiana.

This blog post is going to explore some of these uses and how this plating process is making a significant impact in various industries in the state.

Automotive Industry

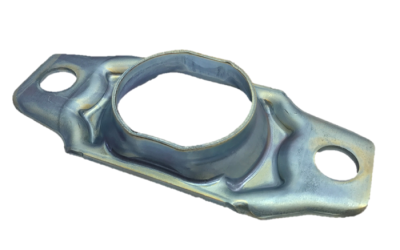

One of the top uses of zinc nickel plating in Indiana is in the automotive industry. Zinc nickel plating enhances the durability of car parts and can stand up against harsh weather conditions. Its high corrosion-resistant capabilities make it ideal for use in car exhausts, brake systems, and fuel tanks. Zinc nickel plating can also be used for decorative purposes in car handlebars, rims, and other metal components in a vehicle.

Aerospace and Defense Industry

The aerospace and defense industry is known for its stringent requirement for materials used in carrying out its tasks. Zinc nickel plating has proved to be up to the task as it can handle severe environments such as high heat and extreme cold. The plating is used in parts like landing gears, missile components, stator vanes, and actuators.

Heavy Equipment Industry

With the heavy equipment industry, durability is always a top priority. Zinc nickel plating aids in this regard by improving the lifespan of various components in heavy machinery in industries such as agriculture and farming, mining, and construction. Examples of such parts include hydraulic systems, couplings, and fasteners.

Electronics

The electronics industry has benefited from the corrosion-resistant capabilities of zinc nickel plating. The metal finish is used in electronic components like connectors, springs, and EMI/RFI shielding. Zinc nickel plating improves the conductivity of these metal parts, making them more efficient in their operations.