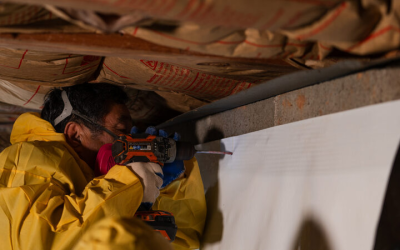

In industries where plasma cutting is going to be used, you should be sure that a constant current DC source is available in the proper output range. Using the wrong power supply cannot only damage your machine but endanger your workers as well. Many production lines use robotic cutting stations to expedite the product output. On a smaller scale human workers can use the cutting torches themselves, but should be aware of basic safety requirements of the tool before they begin.

Plasma cutting and its uses

Plasma cutters are used in a wide variety of applications within the automotive industry, the engineering industry, aerospace industry and the military. Quite simply, it is a very quick and effective way to cut through large amounts of sheet-metal and plate metal which can then be used for vehicles, aircraft, building construction, bridges and much more. Plasma cutting provides a cleaner edge and produces no metal scrap unlike traditional methods. Robotic cutters are used on the production line were a large number of the same items need to be produced in a short amount of time.

What exactly is plasma and what can it cut?

Quite simply, plasma is a gas. By using a combination of heat, ice and steam this gas is a very effective way to cut through metal quickly and accurately. Materials cut by this gas can be used for aircraft, robotics, vehicles, building support, bridge support, weaponry and much more. When sheet metal needs to be cut on a mass level, plasma cutters are quite commonly used as they are quick and accurate when used with the computer design. Any conductive metal can be cut in this manner including steel, brass, aluminum and copper.

Robotics in an industrial application

Robots are quite commonly used for plasma cutting as they are much more precise and do not require the same safety protocols as a human worker. Robots in an industrial situation can withstand the dangerous fumes that may sometimes result from a plasma cut. With new technological advances, robotic cutters can make precise and intricate designs with the aid of a computer program. This allows a much more specific output from your robots than you could ever get from a human worker. In addition to industrial applications, robots are also used within the medical industry as they can withstand extreme radiation and assist in bioengineering.

If you are looking for a steady plasma power supply, be sure to view amp-line.com today.