Welding is a fabrication procedure that uses heat to join two or more separate pieces. In recent times, industry experts have used both spot welding, conventional arc-based welding and laser techniques. Both welding services & laser cutting services in Cedar Hill, TX provide distinctive traits that make them suitable for various cases. The following are the differences between traditional welding and laser welding services:

Traditional Welding Processes

Various traditional welding techniques, such as stop-welding, tungsten inert gas welding, and metal inert gas welding, are still in use today. The conventional welding process remains a long-lasting fabrication solution for many industries. This is because it is comprehended by the manufacturing community due to legacy operations, accommodates accurate and less precise workpiece fit-up, and comes with lower initial investment costs.

The Laser Condition Mode Welding Process

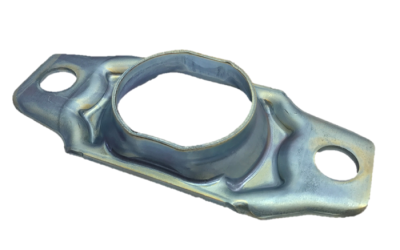

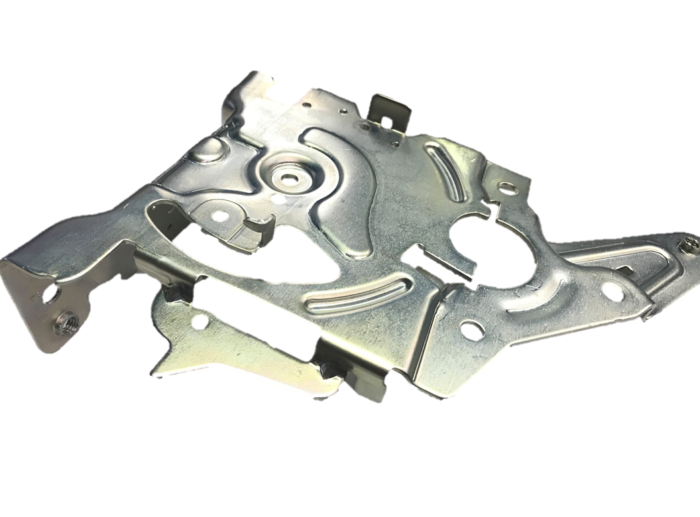

Laser conduction mode welding is an improved metal joining method that utilizes a focused laser beam of an engineered spot size. The laser melt localizes part of the work during the welding operation and, if available, the filler material for simple welds. Depending on the geometry of the joint, part and general structural need, the laser can be utilized to replace traditional welding procedures. Compared to conventional welding techniques, welding has the following benefits: faster processing time, great suitability for thin metals, less heat, and lower threat of distortions and deflections. Laser is applied in the manufacture of foils, thin gauge tubing, fuel rails, thin gauge metal boxes, and hydraulic and fluid control parts.

Contact TriPoint Fab at https://tripointfab.com/ for more information about welding services & laser cutting services in Cedar Hill, TX.