If you are in the market for hydraulic cylinders, you are faced with a variety of options. While some industries and specialists group them into single or double acting and telescopic, others consider them in another fashion. They look at them in terms of specific construction. They divide them into three separate types:

1. Tie-Rod Hydraulic Cylinders

2. Welded Hydraulic Cylinders

3. Ram or Plunger Hydraulic Cylinders

In many industries, the preference is for a specific type. The favored type for the mobile industries is the welded hydraulic cylinder.

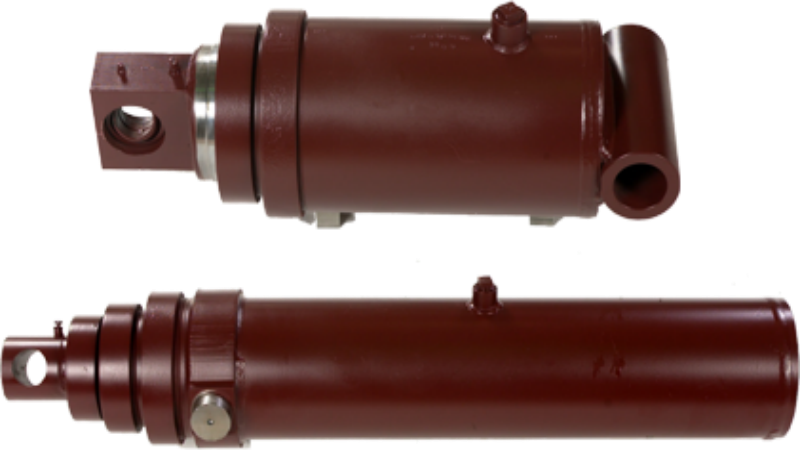

What Are Welded Hydraulic Cylinders?

The construction of welded hydraulic cylinders is the major differentiation factor in determining its type. A tie-rod cylinder, for example, uses tie rods – either in multiple or single forms, to give a cylinder extra stability. Ram cylinders are constructed to act much like battering rams. Their actions pull and do not push. However, the balancing of certain hydraulic cylinders is achieved through welding, hence the name welded hydraulic cylinders.

Welded hydraulic cylinders can be simply fashioned as when an end cap is welded to the barrel’s base end. The head at the rod end can be rendered as either repairable or non-repairable. The repairable version has a head that is threaded allowing it to be removed. The non-repairable version has a fixed head – one that is welded in place.

Advantages of Welded Hydraulic Cylinders

There are several advantages to choosing this type of hydraulic cylinder. They include, but are not limited to the following:

* Versatility: They can be custom-engineered for specific applications

* Durability: The seal packages offer superior protection against contamination

* Longevity: The seal package is capable of increasing the life expectancy of this type of hydraulic cylinder

* Aesthetics: Welded hydraulic cylinders simply look better than the other types when put into place

These characteristics not only makes them a popular choice in several industries but also supply the reasons why they are used in specific applications or employment.

Applications for Welded Hydraulic Cylinders

When it comes down to it, there are applications for the various types of cylinders. Yet, there are certain instances, where the preference will and should, always be for welded hydraulic cylinders. Among the most common uses are the following:

* Where Space Is a Factor: Welded hydraulic cylinders are more slender than other types. This means, they can fit into smaller spaces

* Auto Lifts

* Snow Plows

* Truck Equipment

* Construction Equipment

* Mining Equipment

* Industrial Applications – machinery is more cost-effective when welded hydraulic cylinders are used over the more costly NFPA industrial cylinders

Overall, such favoritism results from the ability of this type of hydraulic cylinder to be more durable and suitable than other types. Where strength, flexibility and long lasting characteristics are required, talk to a specialist in the field. He or she will probably agree that one of your best bets is to employ welded hydraulic cylinders.