There are many different types of specialized load cells on the market today. By choosing a specialized load cell over a general design in a load cell transducer, greater accuracy in measurement is possible and greater life cycles in load cells are also a factor.

While specialized load cells may be slightly more costly as an initial purchase, the increased accuracy, the ease of installation and configuration with the system and the increased life cycle and durability all add up to cost savings in the long run.

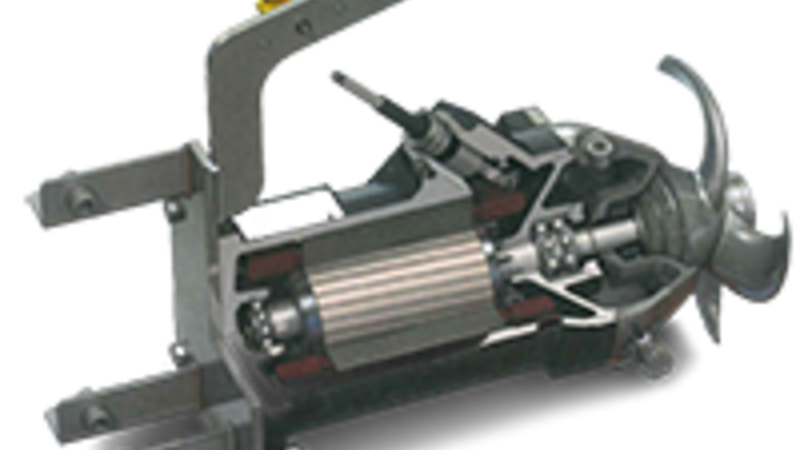

The Pillow Block Load Cell

One of these specialized types of measurement devices is the pillow block load cell. This is most commonly used for web tensioning processes where precision control of the equipment to keep tension within tight tolerances is a factor.

Sometimes known as the under pillow block LC (load cell), this load cell is designed to allow the pillow block to mount directly to the equipment and the load cell. It is commonly used in paper manufacturing systems as well as in textile production or for the manufacturing of rubber, foil or other types of products.

Mounting Considerations

When choosing a pillow block load cell, always check the mounting options for the load cell. Some can only be installed in specific locations and in horizontal or vertical positions. Others are designed for greater flexibility and can mount at any angle and in any position.

Some of these load cells are also designed for use in applications where high humidity or washdown requirements are a factor to consider. These types of load cells have a sealed case that prevents dirt, dust, water or humidity from affecting the accuracy and performance of the load cell, even in very demanding types of environments and applications.