There are several different options when it comes to making plastic parts and components. These can range from different molding options and methods to using ultrasonic welding to create complex shapes and forms.

Another option to consider for many different types of parts and components is the use of custom plastic extrusion. This is most often a top consideration when there is a high volume production requirement for the same parts and components in large single production runs or for ongoing production requirements.

Faster Production

All custom plastic extrusion starts with the design and engineering of the die used to create the shape. In addition, it is important to choose the correct plastic formulation to provide the durability, aesthetic elements and the features required for the part.

Once the die and the plastic formulation have been developed, production is extremely fast. Extrusion is an automated process with limited operator oversight required, so production rates are very fast.

In addition, turnaround times on orders from top companies offering plastic extrusion is extremely short once the die has been developed. Even with the first order, there is still a shorter turnaround time than many other processes, which cuts down the gap between concept and getting the final product to market.

Low Waste

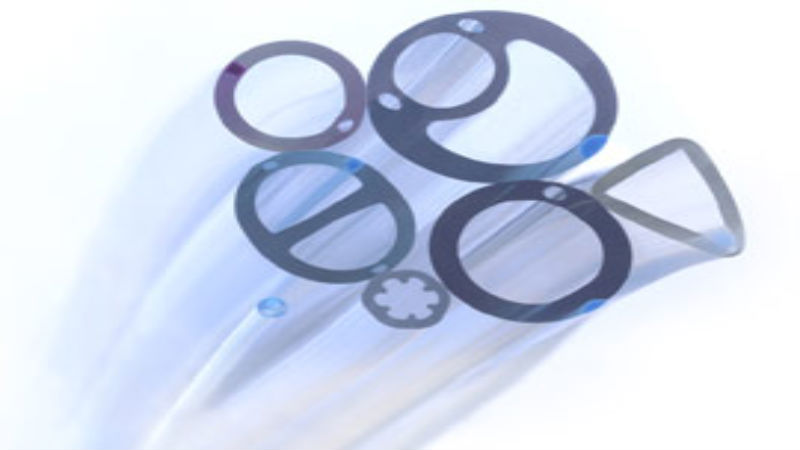

With the custom plastic extrusion process, the plastic is melted to the required temperature to be pushed through the die. This creates a uniform shape and wall thickness that is consistent with the production run as well as between runs.

This process dramatically reduces any waste either in non-conforming production or in wasted material. Different from machining processes, the cost-savings in eliminating wasted material can be significant and continues to grow with production.

Different options in colors, surface finishes and even in the types of materials used in the plastic make this a great option for tubing and other types of uniform shapes required for plastic parts.