Many machine shops enjoy the benefits of VMC equipment. In fact, their low-cost (compared to HMC) is one of their most important features. VMC equipment does many tasks in the shop today, and with modern CNC machinery, you can enjoy the benefits of as many as five axes. However, many shops today are investing in horizontal machining center equipment and here are some important reasons why.

Multi-Step Operation

Because HMC equipment operates from the side (and not over the top like VMC) you can do work from the front, left, and right sides, all at the same time. This makes it possible to do more than one step at a time. This kind of versatility can greatly speed up the production process and make it possible to work with fewer people on hand.

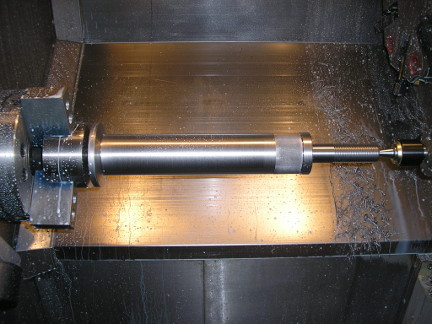

Easier Deep Cuts

With VMC equipment, making deep cuts into workpieces is not always easy. For example, you could have a problem with chip buildup, and this can affect the outcome of your work. Issues like these are not a problem when you use a horizontal machining center. Because the workpiece is vertical, cutting chips easily fall away and there are few chances for chips building up and getting in the way.

Table Adjustments

You have many adjustment possibilities with HMC tables. For example, you can drill holes at one angle, and then adjust the table to drill at another angle. This is easily programmed into the machine, but the process is more complex with a vertical machining center.

Increased Tool Capacity

Storing tools is never an issue with a horizontal machining center. In fact, it’s not uncommon to store as many as 80 tools. This is far more than VMC equipment can store.

Good Investment

HMC equipment is an excellent investment but if it’s not possible, consider hiring a local shop with HMC services.