Grinding involves the use of various materials. The term describes the actual process and the materials that comprise the equipment, as well as the items to be ground. Carbide grinding, for example, may indicate the grinding of carbide inserts or the use of carbide to grind products. In both cases, the equipment uses carbide.

What Is Carbide?

Cutting tools often contain carbide. This carbon compound possesses high hardness. This explains why it is popular both as a cutting tool and for cutting tools. Typically, it becomes a component of such tools as:

* Dental drilling tips

* Dies

* Drill bits

* Heating elements

* Lathe bits

* Router bits

* Saw blades

While many types of carbide exist, those most commonly employed in carbide grinding are:

* Boron carbide (B4C): This type of carbide features high hardness and wear resistance. Applications include low-temperature applications such as grinding wheel dressers.

* Silicon carbide (SiC): As a compound of silicon metalloid and oxygen, this form of carbide may be black or green in color. With the property of high hardness, it is excellent for cast iron and good for a wide range of steels. It produces acceptable results in the carbide grinding of tungsten carbide cutting tools. Green SiC has a quite brittle and friable crystalline structure. It is often employed in the grinding of titanium alloys and austenitic stainless steel.

* Tungsten carbide (WC): This compound of a tungsten metal and carbon is a composite material known as a Hard Metal. Its properties include high hardness (as high as 1600 HV) and high hot hardness.

These are the more common types of carbide used in grinding. Other kinds include aluminum carbide, calcium carbide and titanium carbide.

Why Carbide Grinding?

Carbide and its various variations offer several advantages both as a product and as a grinding tool. Carbide has:

* Superior wear resistance

* High hot hardness

* Resistance to high temperature – because of their high hot hardness

* Nicer finishes

* Improved predictability over steel

It is also, according to those who use it regularly, easier to hold and process and has better dwells.

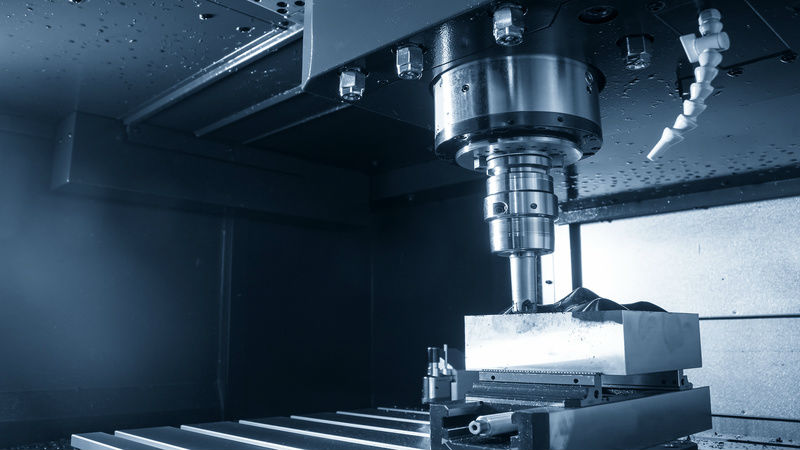

Carbide Grinding

When grinding carbide, care must be taken to be aware of the different types of carbide. While it is obvious that they come in different sizes, shapes and forms, it is important for the operator of the grinder to have a clear understanding of the different properties of each carbide type. Carbides differ from each other in terms of not only optical and physical properties, but also specifications. This includes electrical, thermal and mechanical. An operator must consider every aspect when carbide grinding if the product to emerge is to be if the best quality possible.