Wind turbines are complex machines that require regular maintenance. Recognizing the signs that you need industrial motor repair may help prevent costly breakdowns. Here are some key indicators that your wind turbine’s motor needs repair.

Overheating and Excessive Vibration

Changes in the way your wind turbine operates could indicate that the motor needs repairs. For example, you may notice overheating or excessive vibration.

Overheating is a serious issue that may be due to poor ventilation, overloading, or internal friction. It may also lead to permanent damage, increasing the need for immediate attention.

Excessive vibrations are often a sign of an imbalance or misalignment. Vibrations could lead to further mechanical problems if not addressed quickly.

Frequent Tripping or Decreased Performance

Frequent tripping and decreased performance may be connected to electrical issues. For example, a motor may frequently trip or shut down due to electrical faults or overloading.

A noticeable drop in performance may also be due to electrical faults. However, decreased performance may also come from general wear and tear or mechanical failures.

Oil Leaks and Visual Damage

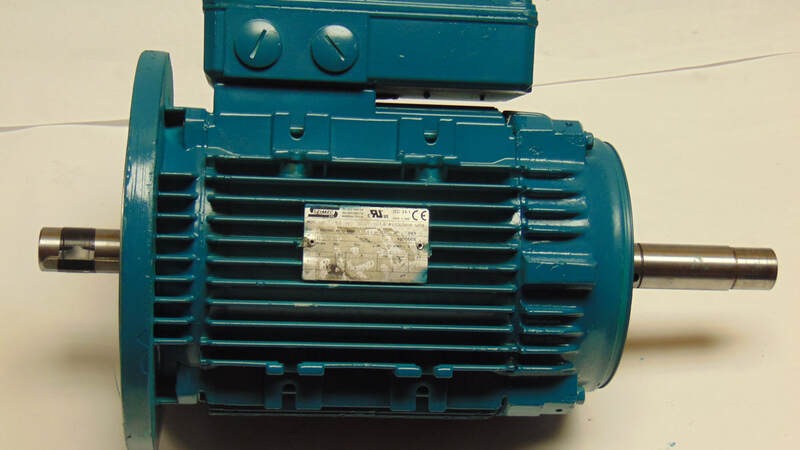

Oil leaks and signs of visible damage are obvious indicators that you need industrial motor repair. Oil leaks can lead to insufficient lubrication, causing increased friction and wear.

Visual damage may include cracks, rust, or worn-out components. These issues could impact the safety and performance of the motor.

Maintenance Alerts

Some modern wind turbines include monitoring systems that provide maintenance alerts. Pay attention to these alerts and address any indicated issues to avoid further problems.

In fact, if you notice any of the signs discussed, don’t delay dealing with the repairs. Timely repairs can minimize further damage.