Creating a wide range of different plastic polymers is definitely one of the best things that chemistry has provided for the world. Just think about all the many different things you see on a daily basis that use plastic. There are tough plastics that are used for building appliances, and soft plastics used for wrapping up snack cakes, and everything in between. One of the most popular forms of plastic today is with the wrapping of products, known as thermoforming. This is where plastic is heated and wrapped around a product. Here are some of the benefits of going with custom thermoformed packaging.

Packaging for Any Product

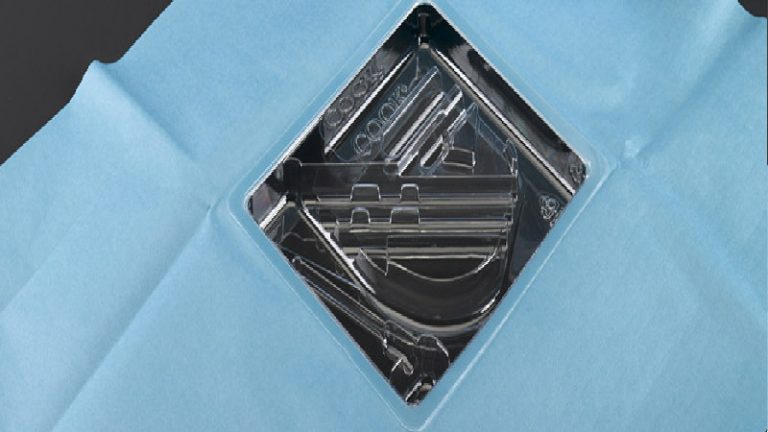

The first big benefit here is the fact that almost any sort of product can be wrapped up with the thermoforming process. This includes different food items that companies sell at stores and in vending machines, to a wide variety of video game gear, computer components, etc. Having tough plastic that’s molded to the product’s packaging provides a lot of security and durability. The ability to custom-fit this packaging to any item is a huge benefit.

Quality Control

Custom thermoformed packaging is also going to greatly improve the quality of the products. For people selling products, you’re not just selling a single item. You’re likely shipping and selling thousands upon thousands of items. Having a more secure form of custom packaging definitely ensures that the quality of the goods will be superior, with less damage and loss.