Thanks to computerized machining methods, milling, boring, cutting, and other operations are faster, more efficient, and more precise. It started with punch cards and numeric control years ago and developed into 5 axis CNC machining services, which use highly advanced machinery. Let’s look at some of the good things you can receive.

Why Five-Axes?

With three axis CNC machining, you have three components, X and Y axes can move in two directions while a machine tool (Z) can move either up or down. However, this offers limited movements. By adding some A and B axes, you can approach the workpiece from just about any direction, and this lets the machinist do many tasks in one step.

Benefits

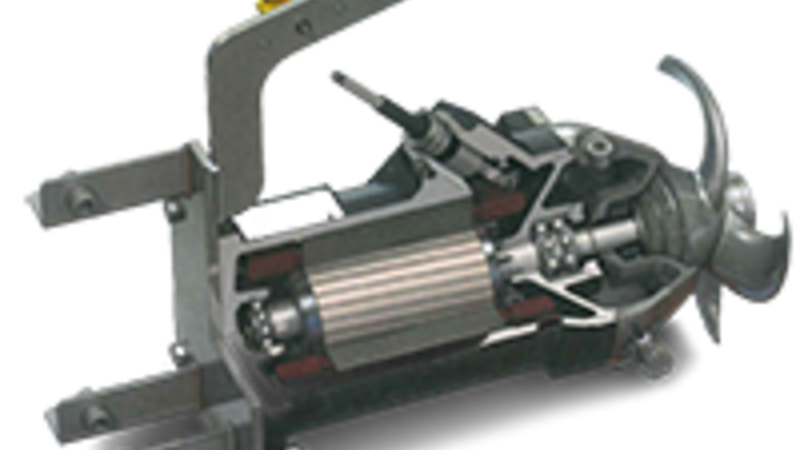

Because you use fewer steps to create parts, more complex parts are capable within shorter timeframes. This is a valuable resource for precision parts in the medical, aerospace, and automotive industries. For example, to make a special impeller or turbo blades, you may need to use more than one machine and machinist. 5 axis CNC machining services can create the part on one machine and quicker.

Greater Efficiency

More than half of all the parts CNC shops produce need machining on five sides of the workpiece. Only a five-axis method can create the parts you need on one machine, and without this kind of machine, your shop efficiency suffers.

Fewer Employees Needed

Because you need fewer people with 5 axis CNC machining services, you can save a lot of money on employee related costs. In fact, it takes a smaller workforce to produce parts on five-axis machines.

Downside

Your company may not have the funds to buy the equipment you need. You may need more space or a larger facility. This is not a problem because you can hire trusted 5 axis CNC machining services for the job.